Aluminum Honeycomb Core

- Mobile: +86-13962238789

- whatsapp: 008613962238789

- wechat: 008613962238789

- E-mail: [email protected]

DESCRIPTION

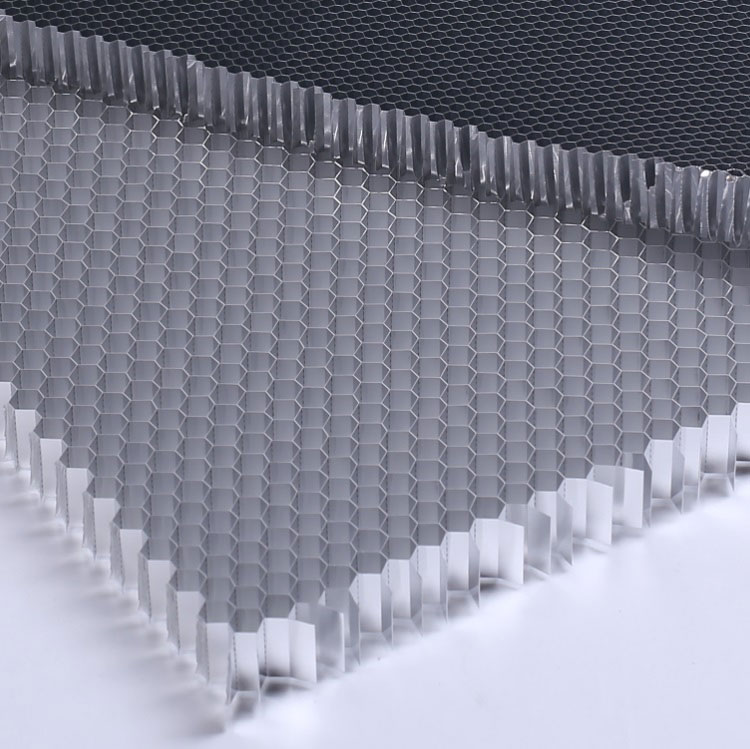

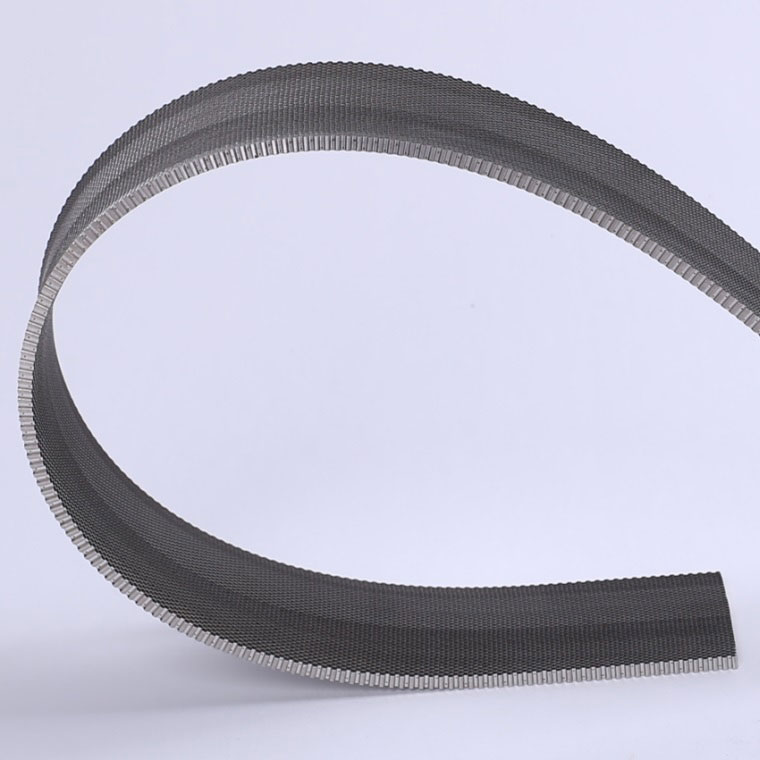

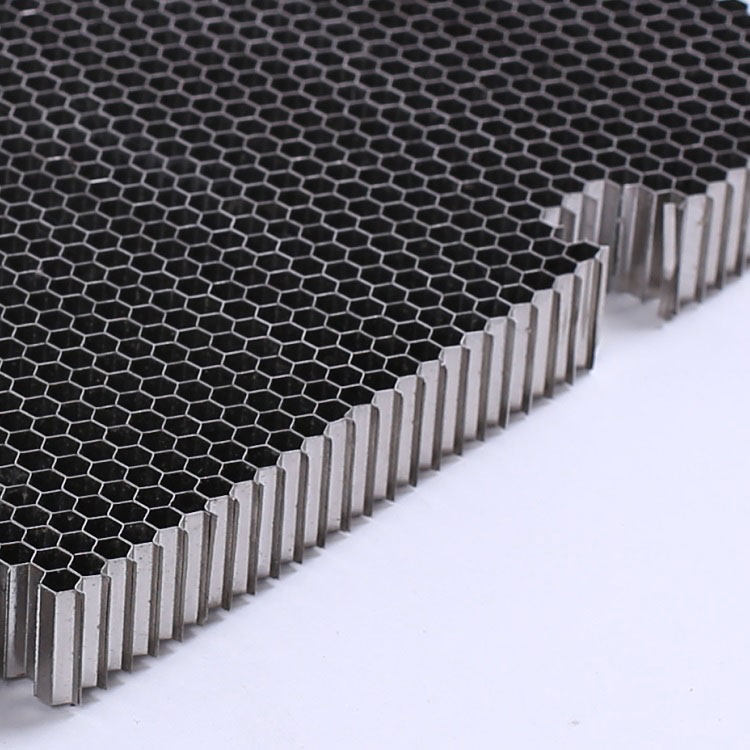

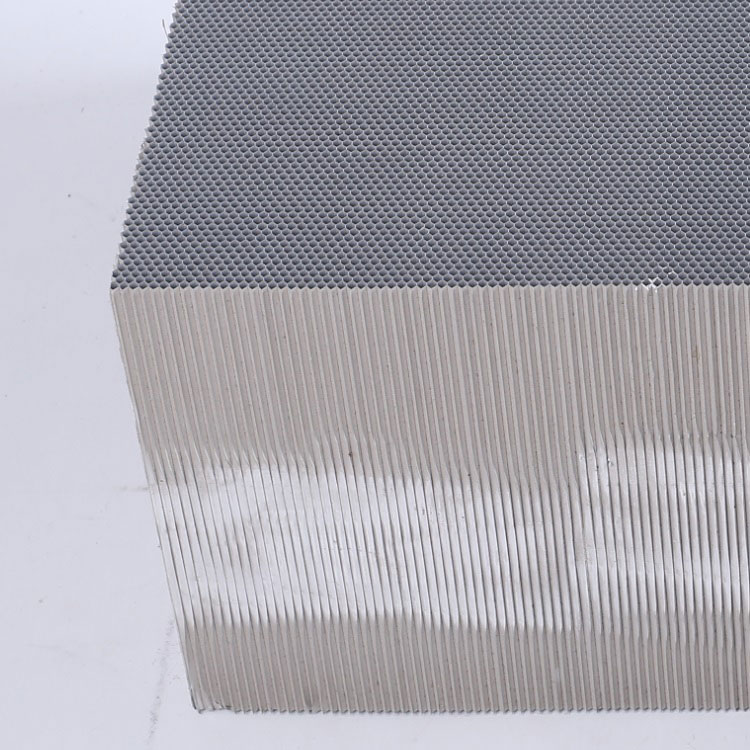

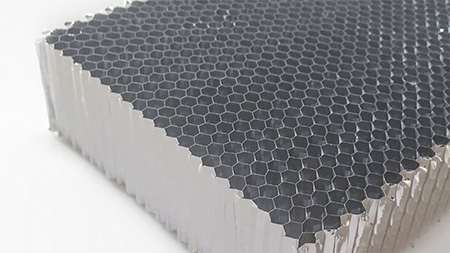

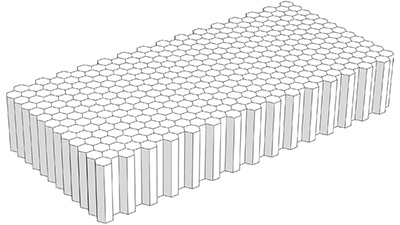

The aluminum honeycomb core is made by pulling apart precision bonded aluminum foil laminates in a uniform manner. Our honeycomb core cells feature an accurate size, with a homogenous and beautiful hexagon, making them suitable for the production of high-quality honeycomb composite panels and fully aluminum furniture. At Aluwedo, the most popular honeycomb core is the ultra-microcellular aluminum honeycomb core, followed by a multi-purpose conventional cellular aluminum honeycomb core.

Material: 3003 aluminum foil and 5052 aluminum foil

Aluwedo’s aluminum honeycomb core is available in the following forms:

• Unexpanded blocks

• Untrimmed expanded sheets and cut to size expanded sheets

• Perforated and unperforated aluminum foil

Executive standard for aluminum honeycomb core:

China Avation Industry Standard “The Standard for durable

aluminium honeycomb core for sandwich structure applications”HB 5443-90

Flatwise compressive and shearing strength

| Density kg/m | Thickness of specifications/l ength of every side | Room temperature(23±5°C) | 150±5℃ | 175±5℃ | ||||||

| Flatwise compress ve strength | Vertical shear strength | Elatwise shear strength | Flatwise compressive strength | Vertical shear strength | Mpa Flatwise shear strength | Mpa Flatwise compressive strength | Mpa Vertical shear strength | Mpa Flatwise shear strength | ||

| 27 | 0.03/5 | 0.53 | 0.44 | 0.24 | 0.35 | 0.22 | 0.17 | 0.33 | 0.33 | 0.16 |

| 31 | 0.04/5 | 0.66 | 0.53 | 0.3 | 0.43 | 0.39 | 0.21 | 0.41 | 0.37 | 0.2 |

| 33 | 0.03/4 | 0.73 | 0.58 | 0.33 | 0.49 | 0.43 | 0.23 | 0.46 | 0.41 | 0.22 |

| 39 | 0.04/4 | 0.98 | 0.75 | 0.43 | 0.66 | 0.54 | 0.29 | 0.63 | 0.52 | 0.28 |

| 41 | 0.05/5 | 1.07 | 0.8 | 0.47 | 0.74 | 0.59 | 0.33 | 0.7 | 0.57 | 0.31 |

| 44 | 0.03/3 | 1.18 | 0.89 | 0.52 | 0.83 | 0.65 | 0.36 | 0.79 | 0.62 | 0.34 |

| 49 | 0.06/5 | 1.43 | 1.03 | 0.6 | 0.99 | 0.76 | 0.42 | 0.94 | 0.73 | 0.4 |

| 52 | 0.04/3 | 1.6 | 1.15 | 0.67 | 1.1 | 0.84 | 0.46 | 1.05 | 0.8 | 0.44 |

| 53 | 0.05/4 | 1.65 | 1.18 | 0.69 | 1.14 | 0.87 | 0.47 | 1.08 | 0.83 | 0.45 |

| 61 | 0.06/4 | 2.07 | 1.18 | 0.86 | 1.22 | 1.08 | 0.59 | 1.13 | 1.04 | 0.56 |

| 66 | 0.03/2 | 2.39 | 1.7 | 1 | 1.65 | 1.24 | 0.68 | 1.57 | 1.19 | 0.65 |

| 67 | 0.08/5 | 2.45 | 1.74 | 1.02 | 1.69 | 1.27 | 0.7 | 1.61 | 1.22 | 0.67 |

| 68 | 0.05/3 | 2.5 | 1.78 | 1.04 | 1.73 | 1.3 | 0.72 | 1.64 | 1.25 | 0.68 |

| 77 | 0.04/2 | 3.1 | 2.18 | 1.25 | 2.43 | 1.59 | 0.85 | 2.02 | 1.53 | 0.81 |

| 81 | 0.06/3 | 3.35 | 2.37 | 1.33 | 2.32 | 1.73 | 0.91 | 2.2 | 1.66 | 0.86 |

| 84 | 0.03/4 | 3.57 | 2.5 | 1.42 | 2.44 | 1.83 | 0.97 | 2.32 | 1.75 | 0.92 |

| 85 | 0.10/5 | 3.67 | 2.54 | 1.49 | 2.48 | 1.86 | 1.01 | 2.35 | 1.78 | 0.96 |

| 106 | 0.10/4 | 5.29 | 3.51 | 2.12 | 3.65 | 2.56 | 1.45 | 3.47 | 2.46 | 1.38 |

| 110 | 0.08/3 | 5.47 | 3.68 | 2.23 | 3.78 | 2.69 | 1.53 | 3.59 | 2.58 | 1.45 |

| 140 | 0.10/3 | 8.53 | 4.99 | 2.98 | 5.88 | 3.65 | 2.04 | 5.59 | 3.5 | 1.94 |

Node strength

| Density kg/m | Minimum unit value kn/m(23士5℃) | Minimum unit (after2-hour boiling) |

| 27-140 | 1.32 | 1.25 |

APPLICATION